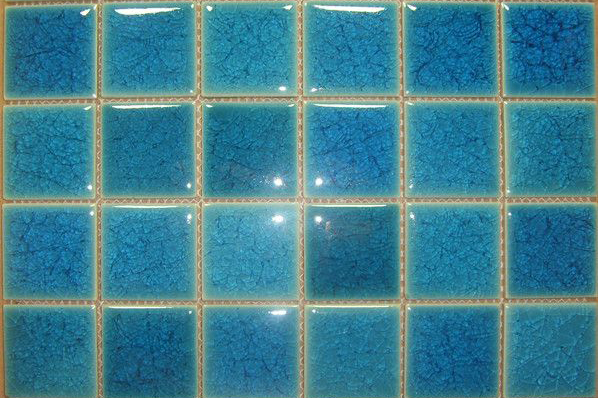

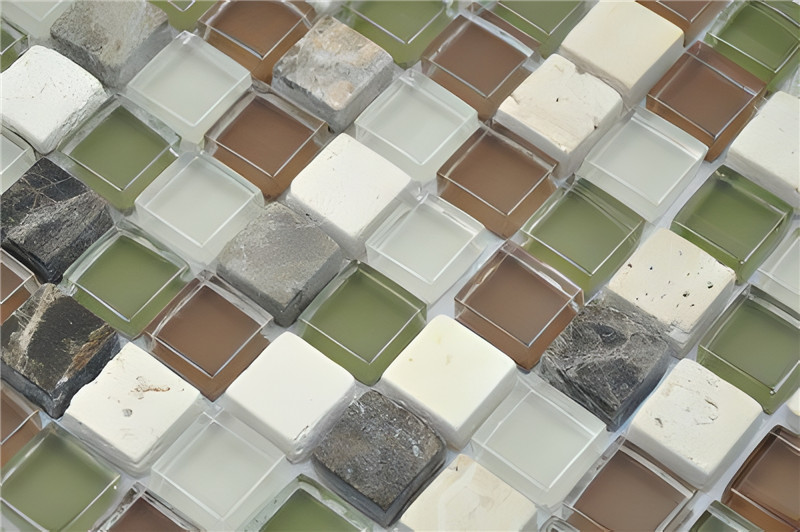

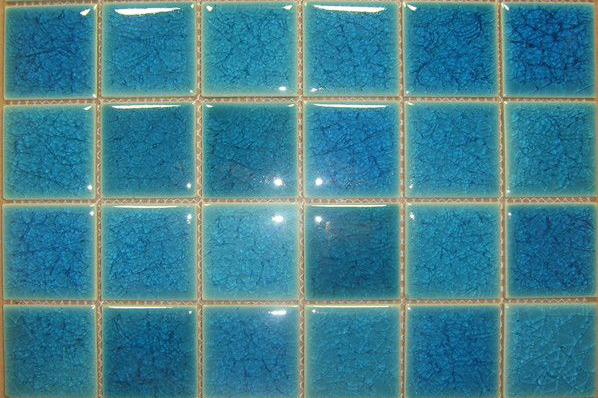

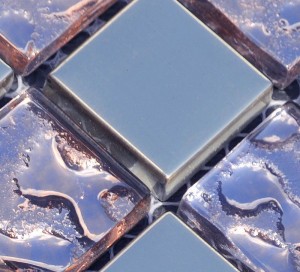

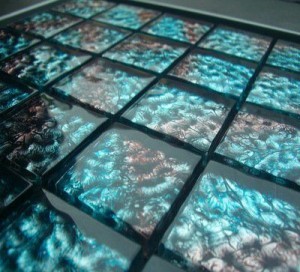

Enemavara enamelled girazi yekugezera uye kunze madziro aripo

Product Description

Enamelled giraziinoreva nzvimbo yegirazi yakachekwa mune imwe saizi yakavharwa nejira remuvara fusible glaze, kupisa kune glaze kunyunguduka, kuitira kuti glaze layer uye girazi zvisimbe pamwechete, kuburikidza nekunyunguduka, kunyungudutsa kana kupisa kugadzirisa maitiro,girazi rinopisa enamelyakagadzirwa ine mavara akanaka uye mapatani. Iine kugadzikana kwakanaka kwemakemikari uye kushongedza, yakakodzera kuvaka kunze kwemadziro emadziro.

Kugadzirwa kwegirazi re enamelled kunosanganisira kugadzirwa kwemavara glaze, kupenya, kuomesa, kupisa, kudzima kana kumisa, kutonhora uye mamwe maitiro.

Pane zvinhu zviviri zvakakosha mukugadzirwa kwegirazi glaze, base glaze uye pigment, base glaze ihupfu hwefusible girazi frit; Pigment chinhu chisina kujairika chinoisa ruvara. Inogona kunge iri inorganic compound kana akati wandei inorganic compounds. Inogadzirwa nekukuya, kusanganisa, kunyura uye kukuya muhupfu mune imwe chiyero.

(1)Base Glaze

Basa rebhesi glaze nderokuparadzira inorganic pigment zvakanyanya, uye kunyunguduka pamusoro pegirazi substrate pane yakaderera tembiricha, uye substrate inobatanidzwa mune yakazara; Kana iyo base glaze yasanganiswa, iyo inorganic pigment ine yakasimba coloring kugona inoidhaya mugirazi reruvara, uye iyo layer yegirazi negirazi substrate inosanganiswa kuita yakazara uye inove ine mavara akapenya girazi. Inyanzvi yekushanda kwechigadziko glaze inodiwa: kunyunguduka kwekushisa kwakadzika, iyo inogona kunyungudutswa pamusoro pegirazi substrate isati yanyorova; Iine kugadzikana kwakanaka kwemakemikari uye kupenya, uye haiburitse makemikari kusangana neinorganic pigment, uye haikonzeri kuti ruvara rwe inorganic pigment pachayo ichinje; Iyo yekuwedzera coefficient iri padyo zvakanyanya neiyo yekuwedzera coefficient yegirazi substrate. Kana kutonhora kuchichinja, glaze haina kuputika uye kupisa.

(2)Pigment

Pigment, imhando yesimbi okisidi kana komisheni, inogona zvakare kugadzirwa neakawanda simbi okisidhi kana makomisheni, zvinoenderana neimwe reshiyo yekukuya, kusanganisa, kupinza, kugeza, kusefa, kuomesa, uye kukuya kuita hupfu hwakatsetseka. Mavara akasiyana-siyana e pigment, kusarudzwa kwesimbi oxide, hapana kupfava, tembiricha ye sintering uye sintering nguva yakasiyana nepigment. Kupararira kwepigment mukushandiswa kune hukama hwepedyo nehukuru hwayo, iyo diki diki, iyo yakakura kupararira (iyo chidimbu kazhinji isingasviki 5 um).

Enamelling

1. Roll yekubikira nzira Roll coating nzira ndiyo musimboti wekuchinjisa roll kudhinda tekinoroji, iyo gobvu yemavara glaze yakaputirwa pamusoro pegirazi substrate uchishandisa rabha roller.

2. Screen printing nzira Iyo nzira ndeyekuisirwa tekinoroji yekudhinda skrini uye tekinoroji yemazuva ano yematekinoroji, kushandiswa kwechidzitiro chekudhinda, iyo glaze slurry, yakaputirwa pagirazi substrate imwe kana anopfuura marudzi e glaze. Wire mesh inogadzirwa nesynthetic fiber kana simbi isina tsvina.

3. Stamping nzira Iyi nzira inoshandisa inochinjika yakapfava zvinhu yakavezwa muchiitiko pateni yechisimbiso, chisimbiso chine runyoro rwemavara glaze paste, uye ipapo yakadhindwa pane yakachena girazi substrate.

4. Nzira yekunamira ndeyekuwedzera uye kuwedzera kweiyo skrini yekudhinda nzira. Iko kudhinda maitiro akaoma ezviitiko zvemavara akasiyana-siyana pasi pemvura pabepa rinokosha. Kana ichishandiswa, mvura inoshandiswa sechisungiriro, uye inonamirwa pagirazi rakachena substrate, iro rinoomeswa uye rinopisa.

Dry

Mushure mekupenya, iyo glaze layer inofanira kuomeswa kune inotevera nhanho. Zvinoenderana neiyo glazing process uye chiyero chekugadzira, kuomeswa kwechisikigo, kamuri yemagetsi kuomeswa uye kuenderera kuomeswa kwemagetsi kunogona kusarudzwa senzira yekuomesa.

Kupisa uye kutonhora

enamelled girazi yakaenzana kudziyisa uye kutonhora zvinoenderana neyakasiyana nzira dzekugadzira, iyo yakasarudzwa maitiro uye michina:

1.Toughening nzira

Maitiro eiyo nzira yekuomesera ndeye kuendesa girazi rakaoma girazi muchoto rinoomesa uye kupisa kusvika 670 ~ 715 ℃, uye nekukasira kuifambisa mumhepo yakadururwa yekudzima.

2.Semi-tempering nzira

Semi-tempering method Maitirwo eiyi nzira kuendesa glazed yakaoma girazi pepa muchoto chekudziya uye kupisa kune imwe tembiricha, uye woiendesa mukamuri yekutonhorera kuti itonhorese. Heating annealing method Iri pepa regirazi rakaoma mushure mekupenya mune inoenderera mberi roller tafura yekudziisa cellar, muchoto mushure mekupisa, kudziya, kupinza, kutonhora uye yakagadzirwa negirazi rakapenya. Iyo yakanyanya tembiricha muchoto ndeye 670 ~ 715 ℃, uye ipapo annealing uye kutonhora kunoitwa zvinoenderana neimwe tembiricha hutongi.

Advantage

1.Mechanical properties

Nekugadzikana kwakanaka kwemakemikari uyedecoration, inogona kuitwa maererano nezvinodiwa nemushandisi kana unyanzvi hwekugadzira maitiro.

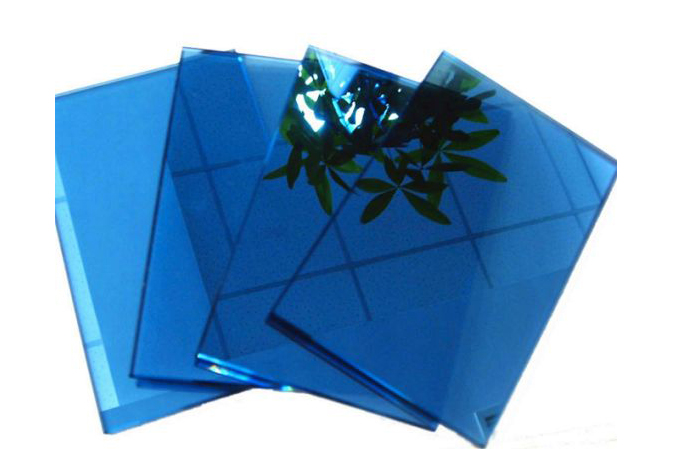

2. Enhanced aesthetic effect yakapfuma ruvara

Exquisite pateni, usapera, usapera, nyore kuchenesa.

Applied range

Interior finishes, foyers uye masitepisi ezvivakwa zvakajairika uye kunze kwekupedzisa kwezvivakwa; Shading uye spacer madziro, zvidzitiro uye zvimwe zvivakwa zvekuvaka zvinodiwa nechivakwa; Glazed girazi partition oven gonhi, chitofu chepamusoro, countertop uye yepamusoro fenicha fittings; Glazed girazi furemu mwenje mumvuri, kupera kwemumvuri, mumvuri uye zvimwe zvigadziriso zvemwenje; Yakapenya girazi rambi mumvuri wemota girazi mupendero, nezvimwe.

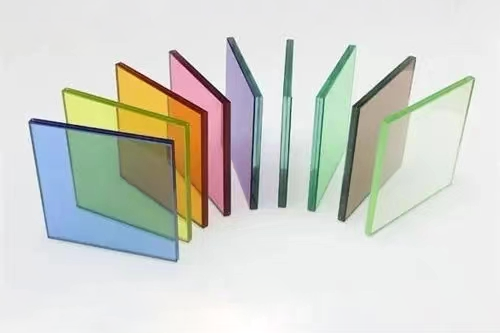

Color

Inorganic pigments inowanzoshandiswa kugadzira inki yegirazi ndeaya anotevera:

1. Tsvuku -- cadmium sulfide;

2. Yero - lead chromate, cadmium sulfide, uranium munyu;

3. Green - chromium oxide;

4. Bhuruu - cobalt aluminate;

5. Brown - iron oxide;

6. Muchena - calcium oxide, kaolin, nezvimwewo.

7. Dema - iridium oxide, manganese oxide uye mamwe masanganiswa;

Production Qualification

Zvigadzirwa zvekambani zvakapfuuraChina inomanikidza mhando system CCC certification, Australia AS/NS2208:1996 chitupa,uyeAustralia AS/NS4666:2012 chitupa. Kuwedzera kusangana nenyika kugadzirwa mitemo, asiwo kusangana mhiri kwemakungwa musika unhu zvinodiwa.